For single-sided V-shaped groove, single fracture flame can be used to cut the groove; On the contrary, the V-shaped groove on both sides can be cut by multi head fracture flame, and the cutting process can be carried out by the same cutting equipment. Thick plate materials sometimes need J-shaped or U-shaped grooves, which can save welding metal compared with double-sided V-shaped grooves. Sometimes it is necessary to consider whether casting and forging structures can eliminate the complex cross-section of weldments, simplify welding design and reduce manufacturing costs. For important parts of structural connection, using expensive materials, such as a small amount of surfacing alloy instead of general welding materials, can achieve good results. When crimping, sealing parts or reinforcing plates need to be added to parts, workpieces manufactured by welding method shall be considered to replace forged parts or machining tools.

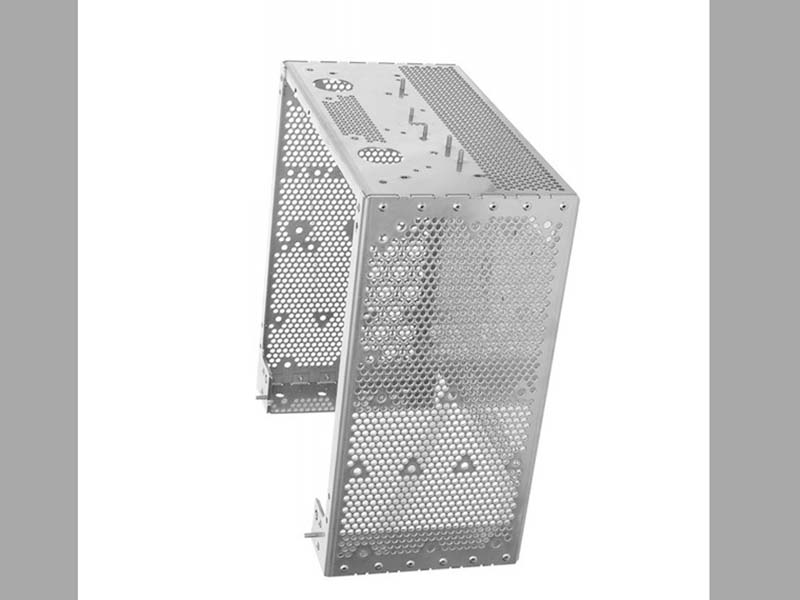

QUICK LINKS:>>> Sheet Metal Frame | Sheet Metal Housing | Sheet Metal Chassis | Metal Kiosk Enclosure | Sheet Metal Cover | Sheet Metal Parts Components | China Sheet Metal Manufacturer | Custom Sheet Metal Parts | Metal Enclosure Manufacturers | Sheet Metal Cabinet | China Sheet Metal Parts | Sheet Metal Bracket | Sheet Metal Parts Manufacturer | Custom Electrical Enclosures | China Sheet Metal Fabrication | China Metal Parts Manufacturer