Tag: sheet metal structural design

Basic knowledge of spot welding

Spot welding is usually divided into two categories: double-sided spot welding and single-sided spot welding. During double-sided…

What is the role of auxiliary gas in laser cutting machine?

The main functions of auxiliary gas used in laser cutting machine are as follows: 1. Most of…

Necessary for making sheet metal! Detailed explanation of cold rolling steel characteristics

Product Name: cold rolling steel Code: SPCC, CRS (SPCD: cold plate for drawing, SPCE cold plate for…

Plastic dipping (sheet metal surface treatment)

Impregnation molding is also known as coating, thermal immersion and thermal coating. Impregnation molding is a plastic…

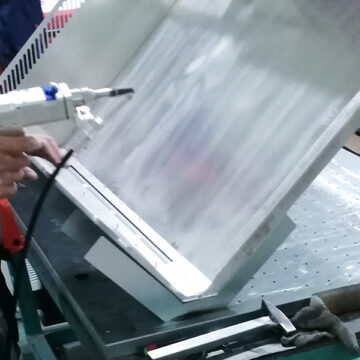

Press riveting link

The press riveting link of sheet metal parts refers to the deformation of sheet metal materials through…

Problems in structural design of sheet metal parts

The influence of processing technology is ignored in the structural design of sheet metal parts. The structural…

Brief introduction of embossing process and coining process

Embossing and embossing processes are widely used in sheet metal parts, including label pasting position indication, product…

Some measures to improve the quality of sheet metal parts

(1) Eliminate various factors that may affect the quality of sheet metal. In the process of sheet…

Characteristics of laser cutting

Compared with other thermal cutting methods, laser cutting is characterized by fast cutting speed and high quality….

How to effectively improve the quality of sheet metal processing?

With the increasing number of domestic sheet metal processing manufacturers, the competition of sheet metal processing has…